A centrifugal fan is a fan in which air flows in a radial — or perpendicular — direction relative to the fan shaft. This is in contrast to axial fans, the type commonly used for household cooling, in which air flows parallel to the fan shaft. While axial fans can move large volumes of air, centrifugal fans are better suited for applications requiring high air pressure. For this reason, centrifugal fans are used in many industrial processes and in air pollution control systems.

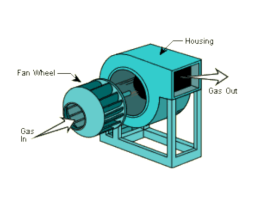

Parts of a centrifugal fan include the fan wheel, fan housing, drive mechanism, and inlet or outlet dampers. The fan wheel consists of fan blades mounted on a hub, which is turned on a shaft that passes through the fan housing. Air enters the fan through the center of the fan wheel, then turns 90° to pass over the fan blades and exit the fan housing.

The drive mechanism of the fan may be direct, belt, or variable drive. Which drive mechanism a centrifugal fan features determines what speed the fan moves at, and how much this speed can be varied. For direct drive, the fan wheel and the shaft of the motor are directly linked, so that the fan’s speed is the same as that of the motor shaft and cannot be varied. One or more belts are used to connect the fan wheel and motor shaft in a belt driven mechanism, and the speed of the fan depends upon the ratio of the shaft sizes. Variable drive fans allow the fan speed to be varied through the use of hydraulic or magnetic couplings.

Blades on a centrifugal fan may be forward, backward, or radial. Forward blades are curved in the direction of fan rotation, have high efficiency, and may be built with small dimensions. Backward blades may be either curved backward or straight. They have high efficiency and low energy requirements and noise emissions — and straight backward blades are also self-cleaning. Radial blades extend straight out from the fan hub, are self-cleaning, and are often used in air pollution control systems because they are least sensitive to particulate build-up.

Centrifugal fans are used in many industrial processes because they are able to produce large increases in air pressure. They are often used in grain drying and and greenhouse ventilation. These are also common in air pollution control as well as heating, ventilation and air conditioning (HVAC) systems.