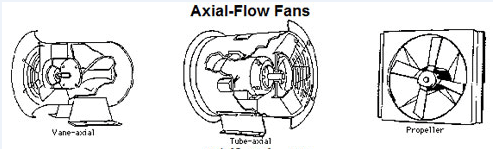

There are two main types of blowers, which are the centrifugal and the axial flow blower. Each of these types will have their advantages and disadvantages and they will each have applications for which each is best suited. This means that each type will have areas where it is better than the other making it the ideal option that particular application. The main differences of the two types of fans stretch beyond the application and into the design aspect which is where the major differences lie. Each has its unique features in terms of structure and that is what gives the difference even in the naming. This explains the main reason for the name, axial flow blowers.

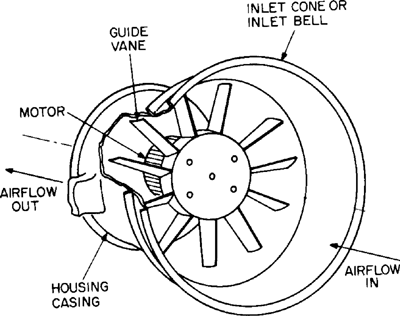

Below is a brief overview of the main features in an axial flow blower in terms of design.

The bellmouth

This type of blower will have an axial flow that will be built into a casing that will also contain the drive motor, the impeller as well as the guide vanes for the outlet system. Some blowers will however, not have guidance vanes and will instead have a mounting bracket for the motor. The main purpose of the bellmouth will be to achieve velocity distribution, which is uniform at the front of the impeller which in turn ensures that the impellers get full surface area exposure.

The diffuser

Large blower will be designed with diffusers on the outside to the lowest possible losses in conversion of the dynamic head to static pressure. The designs of the diffusers will often vary depending on the blower in question. The design aspect that highly determines the design of the diffuser is the presence or absence of a guide vane system. This makes the axial flow blowers the most common equipment in most commercial setups.

The impeller blade

The impeller is yet another key component feature that will be found in any fan on an industrial scale. As is with the case with centrifugal fans there will be different design for the various impellers and it is this design that will count a lot to the possible applications of the fan. The conversion of energy will actually take place on the impeller blades and this means that a fan will only be as effective as the impeller blades it has. Manufacturers therefore try their very best to ensure that minimal energy is lost at conversion as a way of making the entire system efficient and cost effective to run and maintain.