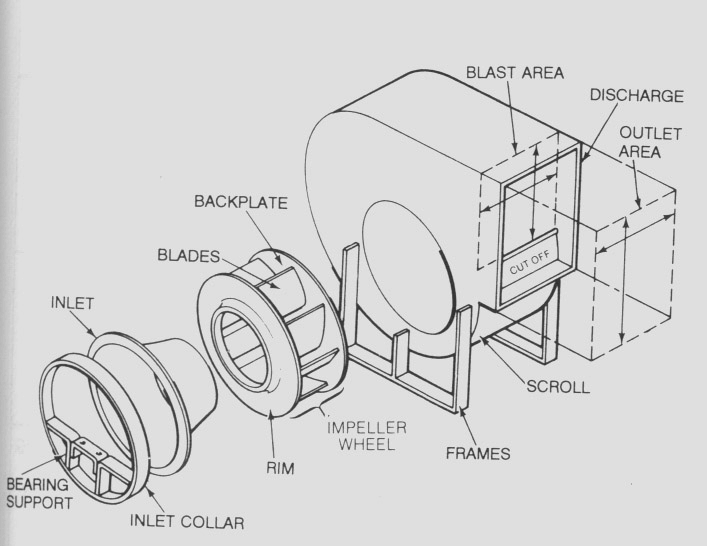

The centrifugal fans have become important machines in a number of industrial applications. A fun system is made up of a number of elements that are assembled together. They complement each other to ensure that the system attains the required level of air flow. Below is an image of a centrifugal fan assembly:

.

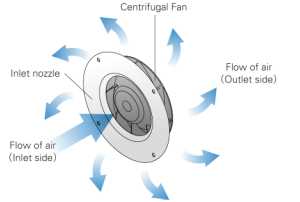

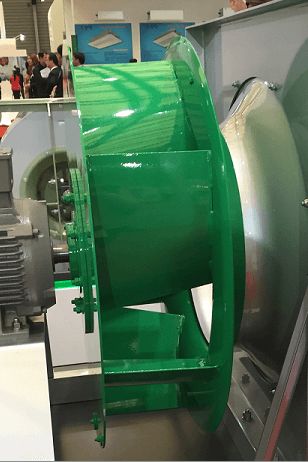

They can increase the air pressure either through a centrifugal force or kinetic energy. The centrifugal force is created by the rotating centrifugal fan blades. The air column trapped between the fan blades is subjected to this centrifugal force. Furthermore, the rotating impeller imparts kinetic energy to the air. This result in the total pressure, which is basically the sum of the static pressure and the velocity head.

The use of airfoil centrifugal fan blades has also gained popularity in the recent past. Of course, they are expensive, however, for large systems where efficiency is a crucial aspect then they are justified.

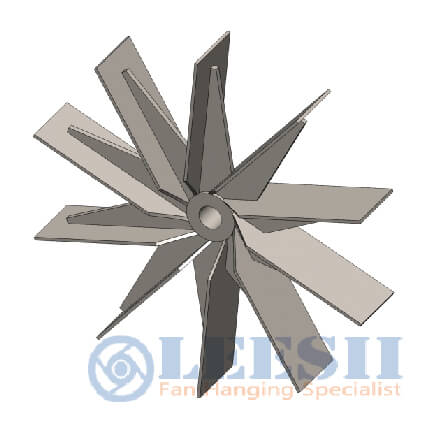

Types of centrifugal fan blades

The available fan blades have varying degree of performance and hence the choice for different applications. When you’re planning to purchase the centrifugal fans, it is important that you evaluate the fans performance curves. Each fan has a unique performance curve. Your manufacturer will provide you with the required documents for every fan you purchase.

1.The backward-curved blades

They are popular for their stability and high efficiency. It is also important to note that they have a self-limiting power feature. Therefore, the fan must be designed correctly to avoid chances of overheating or burning out in case there are changes in the operating conditions. Again, as the fan’s pressure drops, the flow rate is likely to go up. NOTE: Remember to use the fan performance curves as your reference whenever you’re installing a new equipment.

2.The radial blades

The performance of the radial and the backward fan blades is almost the same except for the reason that they can overheat easily. This is for the reason that, an increase in the flow rate increases the amount of power.

Generally, cleaning these fans is much easier, thus, it’s common in a number of industrial applications. The blades are also stronger than the other centrifugal fan blades.

3.The forward-curved centrifugal fan blades

This is the third category of blades that are common in a number of industrial applications. However, it is important to note that this equipment is associated with quite a number of instability issues. They can burn out easily since an increase in flow rate results in an increase of the fan’s power. In contrary, these fans are quieter than the radial and the forward-curved centrifugal fan blades.

When you are thinking of installing any centrifugal fan, you need to choose the three major blades that are available in the market. They have their unique advantages and disadvantages.