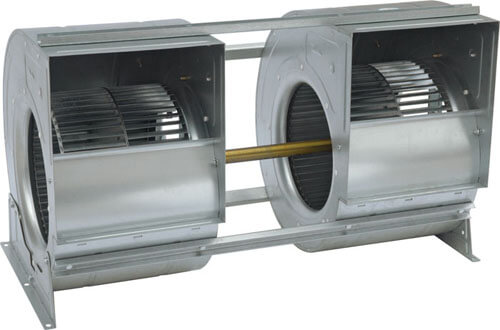

Double inlet centrifugal fans will come in a wide variety depending on the consumer application. They will also range in design and size depending on the same. One of the more specific types of centrifugal fans is the double inlet fan variety that is best suited for certain applications. Other than the double inlets for air as its name suggests, it also has certain key features that set it apart from other fan types.

The most features that standout in these type of fans is the variety in drive systems. These fans will come in one of three basic drive systems.

- Direct drive

This is one of the more popular drive systems for double inlet centrifugal fan designs. Most of these will have a forward curve type blower. Manufacturers will typically offer fan motors that have cooling systems since these types of fans are used in conditions that can get very hot. In instances where they are to be used with flammable air conditions the systems are made to be spark proof for maximum security. The motor shaft will usually be the mounting base for the impellers.

- Belt drive

This type of blower system comes with extensions for steel shafts that come with a variety of running bearings. This type will either have a v type pulley system or a flat pulley. This will of course depend on the size of the fan in question. The shaft and bearing mechanisms will typically be mounted on specialized plates for safety and stability purposes.

- Couple drive

This drive system comes with double blowers to match the size of the fan. This is usually necessary for very high performance scenarios. The design is similar to that of a belt drive system only that it has a “couple blower system” instead. This system requires to be cooled constantly an aluminum air cooler disc systems are the best for this case.

Other key features of these fan systems will include the efficiency with which they operate. This makes them ideal for most industrial applications. In an age where all manufacturers are trying to improve on efficiency, this is the most popular choice in centrifugal fans. This fan system also has reduced power consumption which increases power saving due to the motor as well as design. Several industrial players therefore opt for this type of fan system in their factories.